Mitigate Supplier Risk

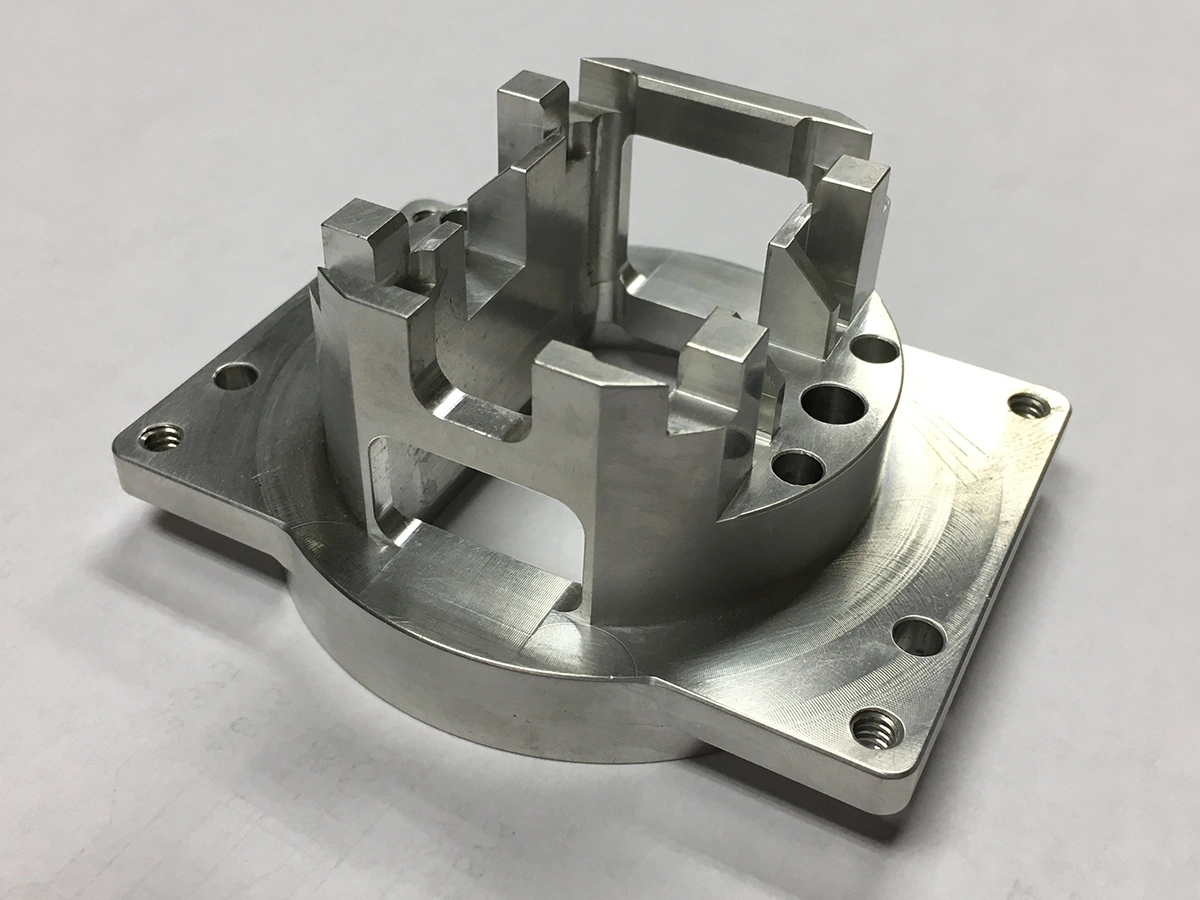

Precision machined parts, assemblies and weldments

PE Certified design & build of fixtures, platforms, and tooling

Fixtures, gages, and assemblies

Prototype to high-volume production parts

Laser and plasma cutting, forming, robotic welding, powder coating

All inspection & quality CERTS provided at shipment if required

We have diverse capabilities to meet standard and special project requirements at competitive lead times. First-time quality is guaranteed as each order is inspected to ensure conformance and quality. Our team responds to RFQs quickly and efficiently, and we have options to meet your most critical implementation dates.

General Capabilities

- Large castings (design and build <44,000 lbs.)

- Steel plate inventory & services

- ¼” to 15” thickness x 120” x 360”, AISI A36, 44W, 1020, 1045, 4140

- Blanchard grinding (max weight 30,000 lbs., 120” x 120” x 60”, 144” diagonal)

- Laser cutting (max 54’ x 12’ x 1”)

- Plasma cutting (max 10’ x 270”)

- Sheet metal fabrication and forming

- Shot peening

- Surface grinding

- MIG, TIG, and Arc welding (AWS & CWB certified)

- Tolerances held to .0002"

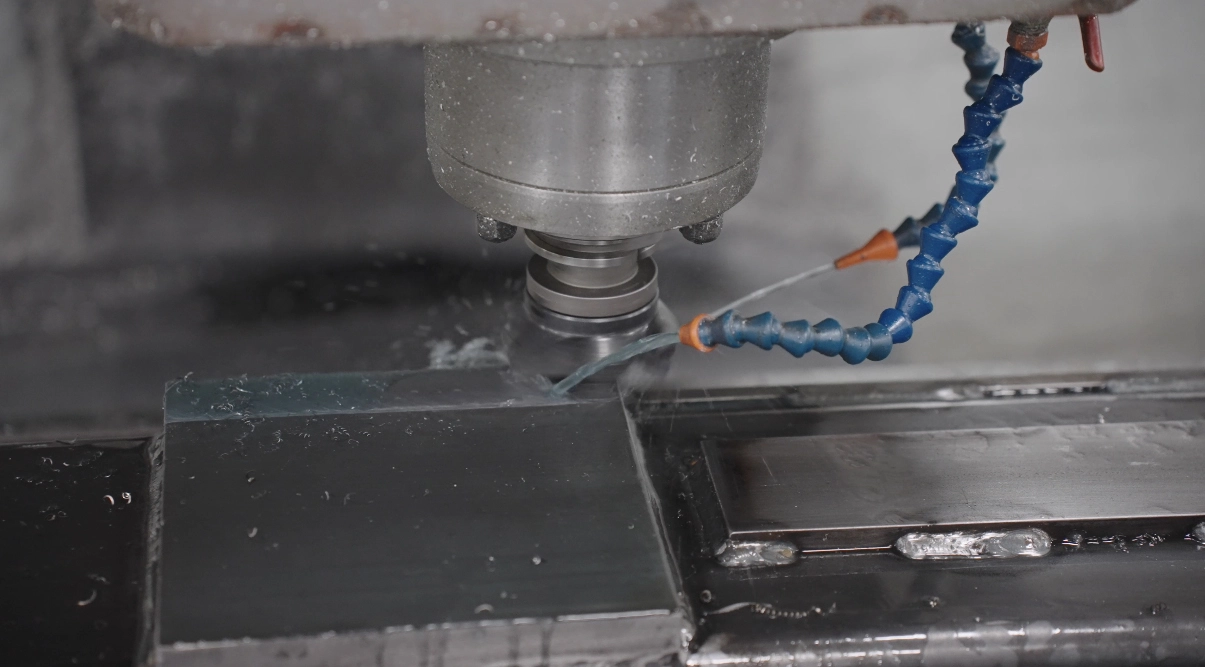

Machining

- Vertical mills (max 138” x 320”, 3 axis)

- Vertical mills (max 102” x 165”, 4 axis)

- Horizontal mills (max 80” x 120”, 4-6 axis)

- CNC turning (max 25” x 80” 1-3 axis)

- Planer mills (max 120” x 360” max 2” thickness)

- Wire EDM (max 13” x 21” x 16”)

- 40-ton machining bay crane capacity

- Swiss Screw

Certified Machine Shops

Let Us Solve Your Precision Tooling & Fabrication Challenges

We view our clients not just as customers, but as valuable partners.

Contact Us Today