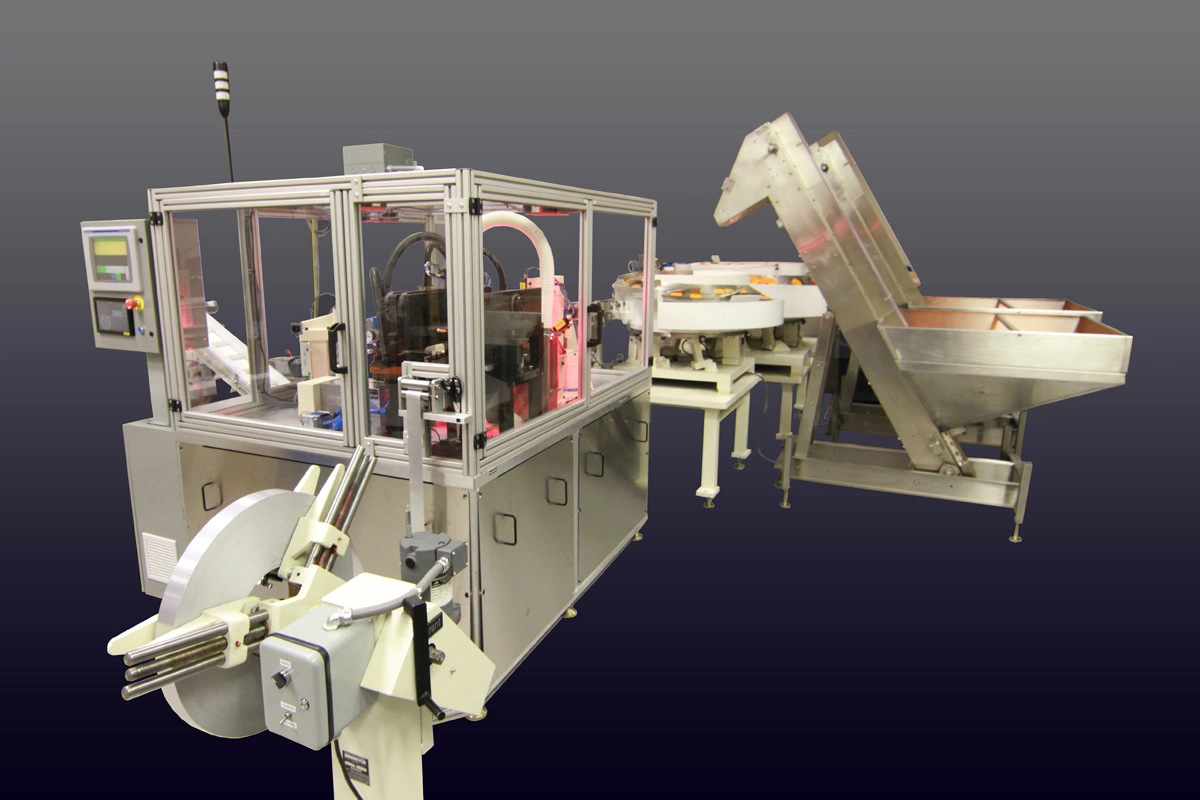

Plastic Cap Assembly/Inspection Machine

Challenge: Engineer a machine solution that assembles and inspects plastic caps for the Food and Beverage Industry.

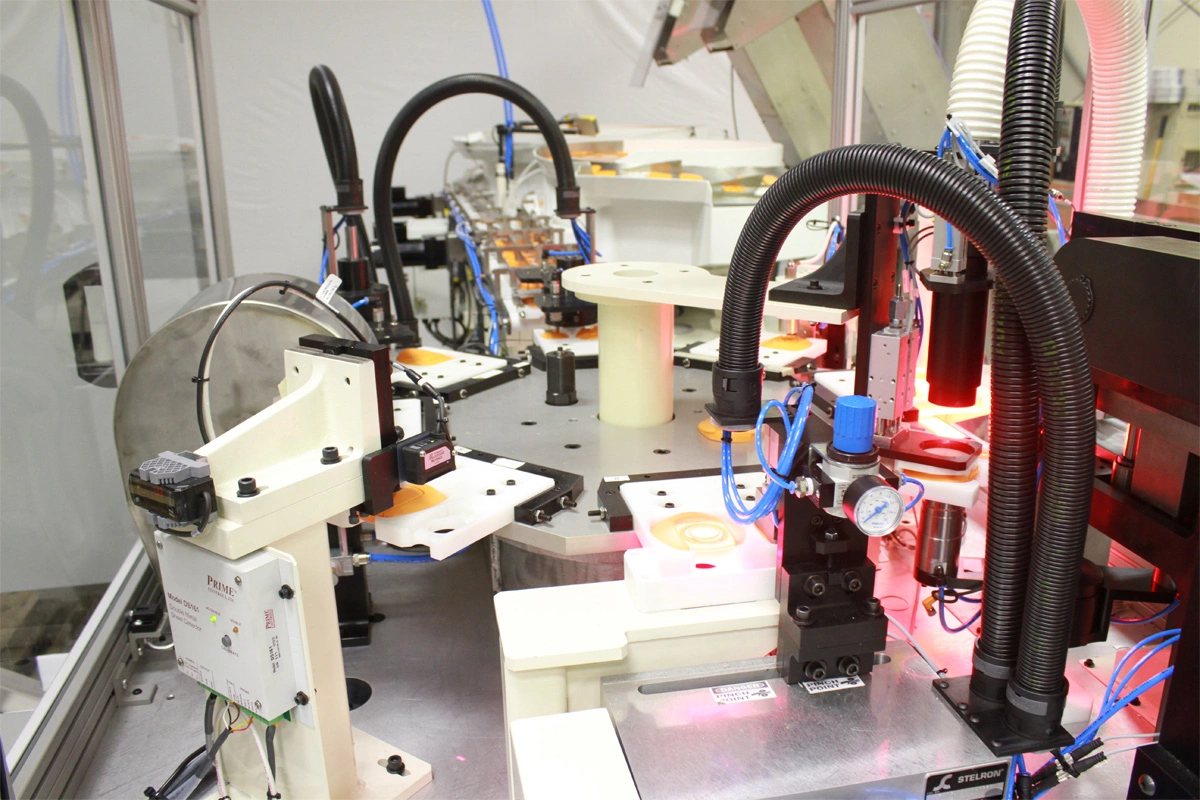

Solution: This is a fully automated system consisting of a rotary dial with a pair of bowl feeders, a pair of exit conveyors, and synchronous pick and place units. Operations required are divided into steps performed at separate stations which include:

- Loading the dial

- Hi-pot test

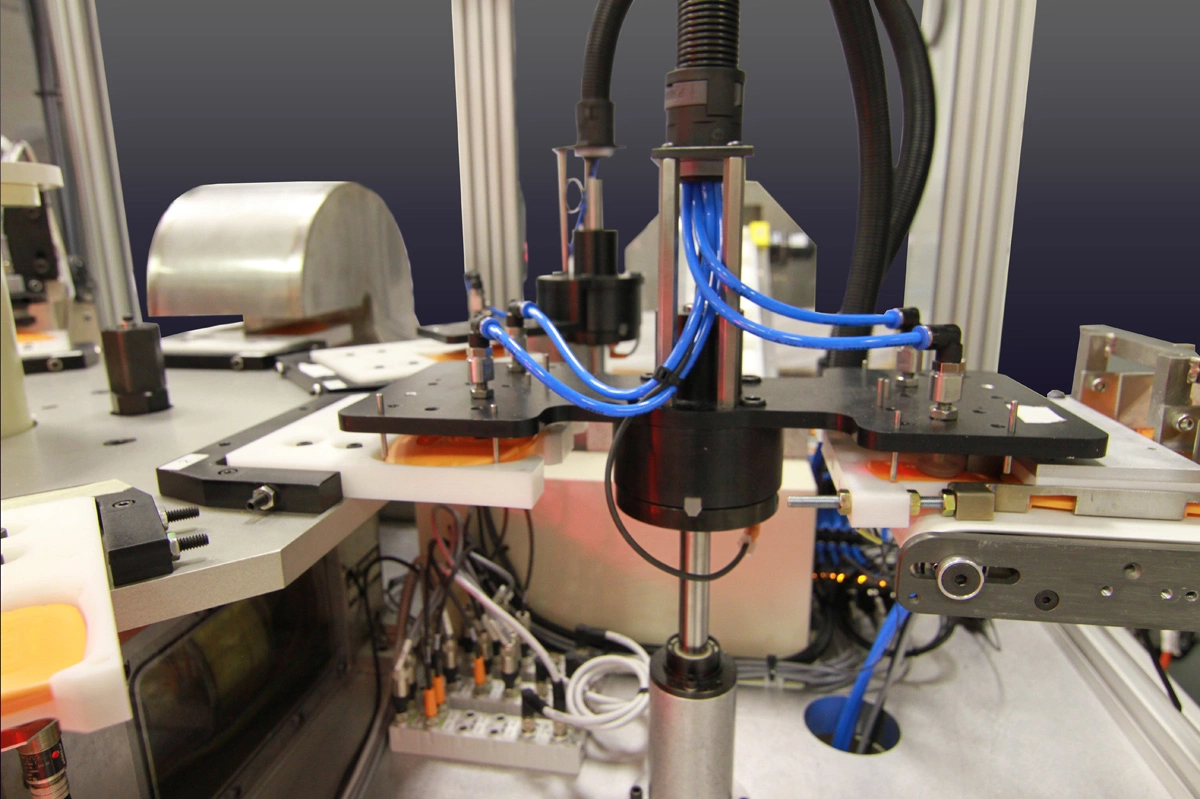

- Sealing ring installation

- Sealing ring orientation vision inspection

- Short shot vision inspection

- Pin hole vision inspection

- Cap assembly

- Reject removal

- Unloading good parts to the exit conveyor

Sealing ring orientation, short shot, and pin hole vision inspections are performed prior to cap assembly.

This machine runs at 3600 parts per hour with an O.E.E over 90%.