Thread Inspection

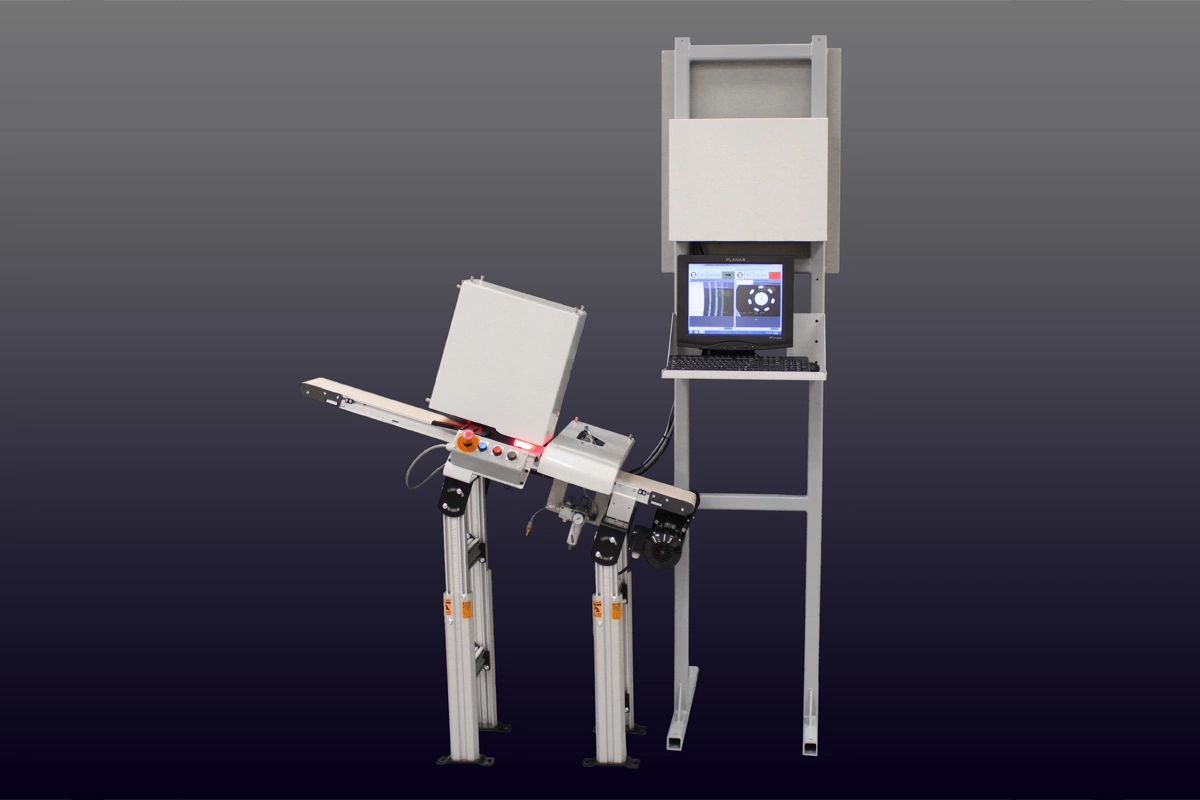

Challenge: Develop a machine to inspect internal threads for a customer in the Consumer Goods Industry.

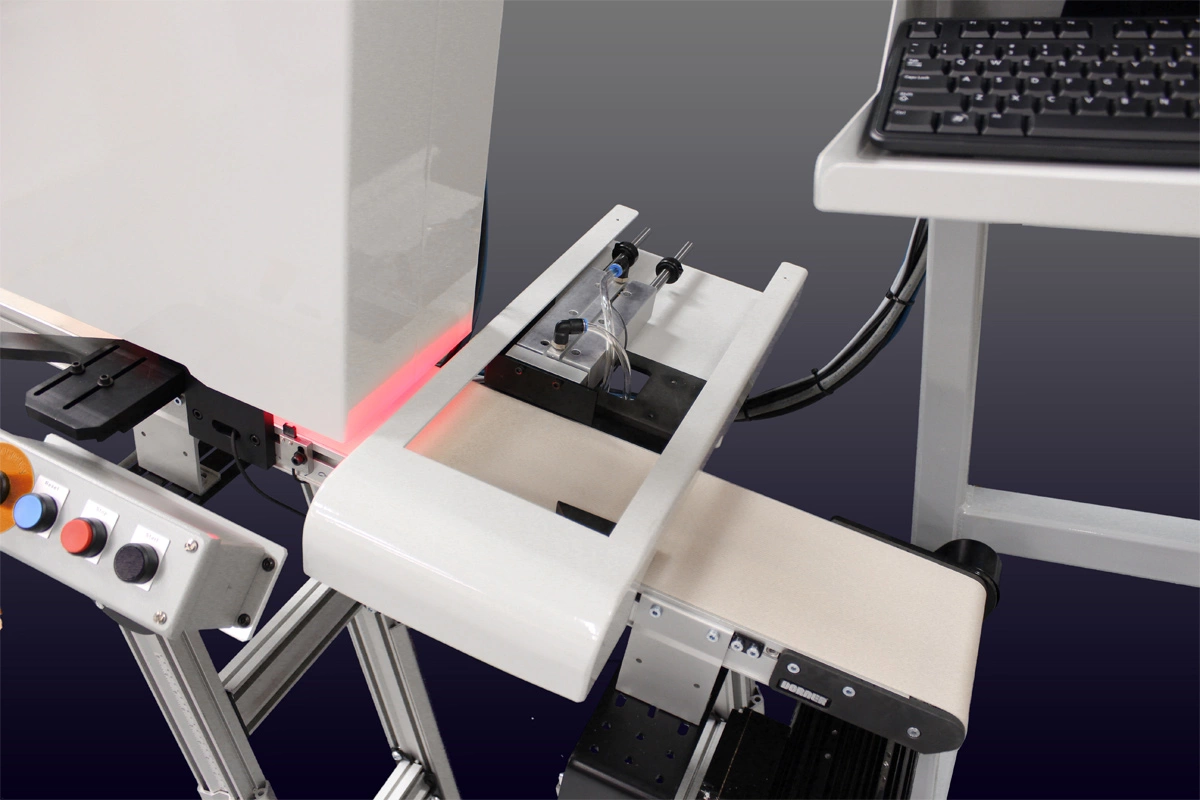

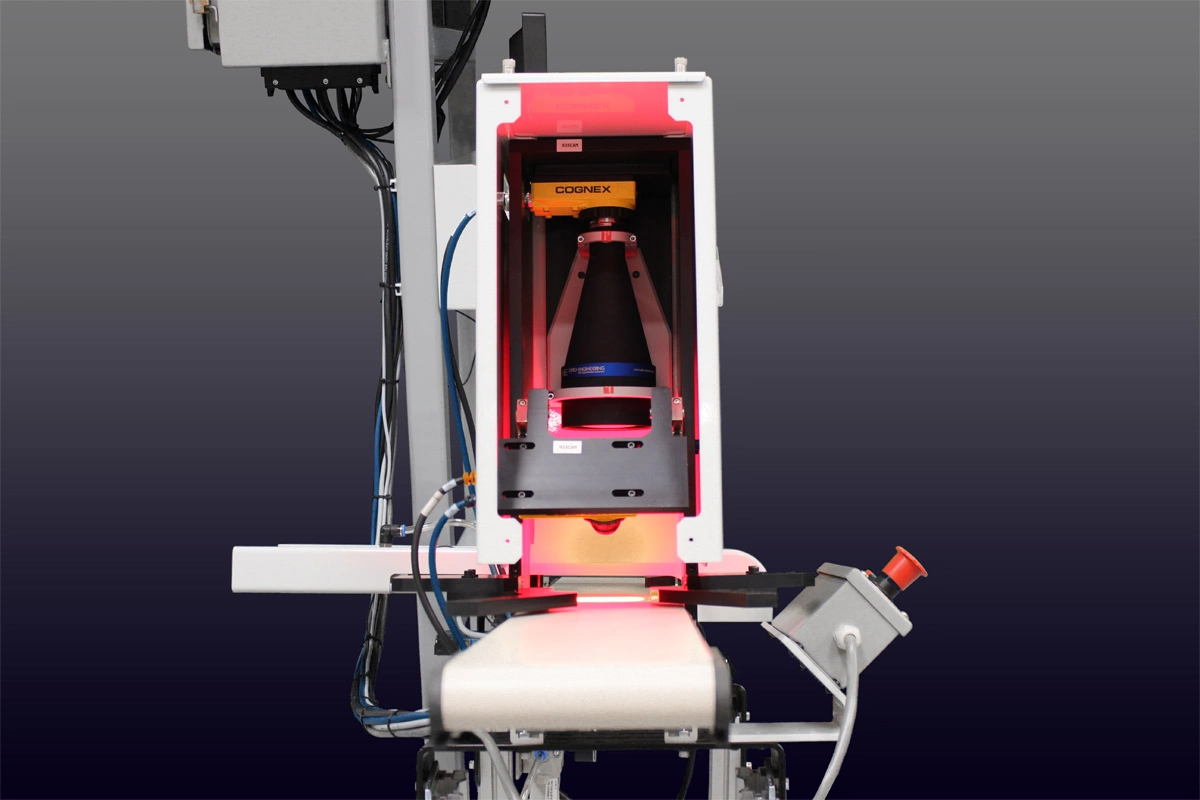

Solution: This machine inspects internal threads for minor diameter and pitch. Parts are dropped onto a conveyor and guided through an inspection tunnel.

The conveyor moves the cap under two high-resolution digital cameras, where back lighting through the conveyor illuminates the part. One camera performs the inspection on the inner and minor diameter. The second camera inspects the thread pitch to pass or fail the part based on acceptance criteria programmed into it. Failed parts are diverted off the conveyor to a reject bin. Accepted parts continue off the end of the conveyor to subsequent conveyors and/or material handling equipment.

The equipment exceeds speeds of 120 parts per minute.